How To Choose A Suitable Welding Table in 2024? - Ultimate Guide

WHAT IS A WELDING TABLE?

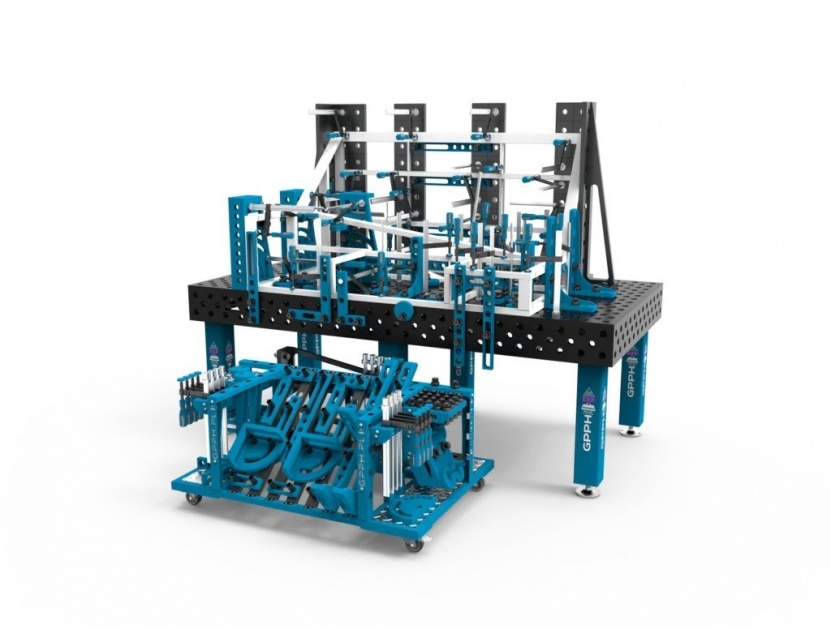

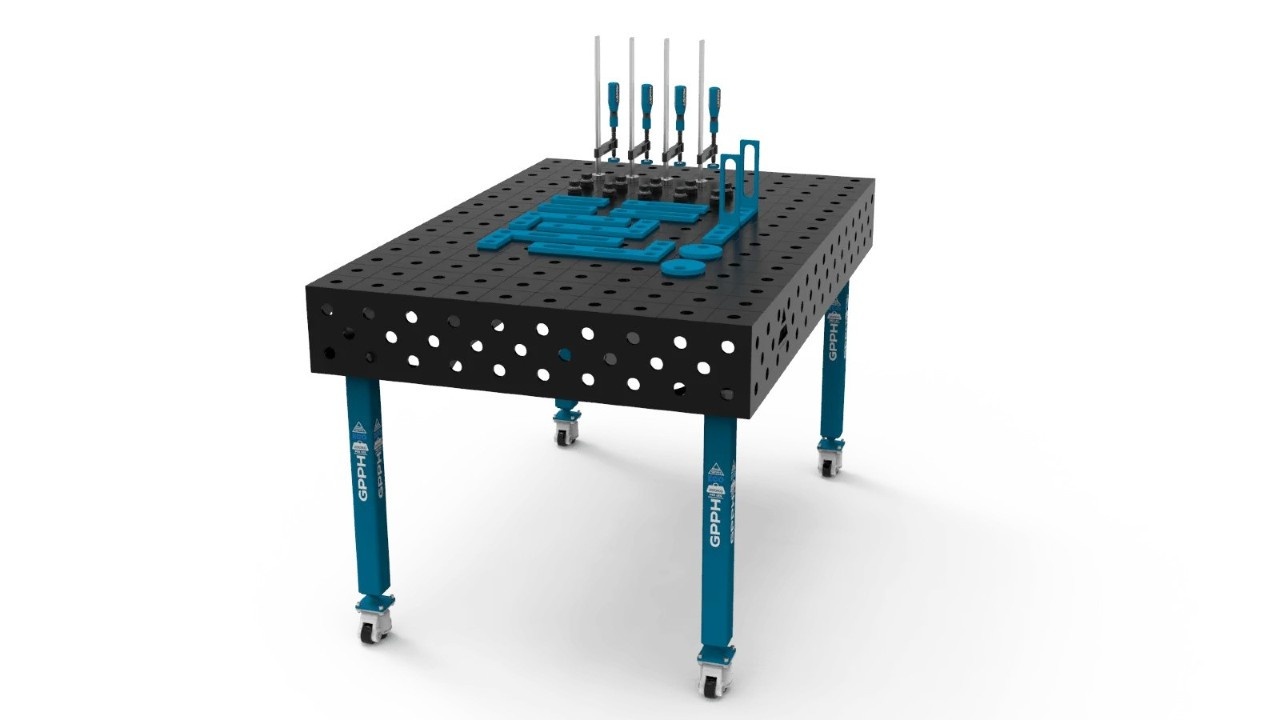

A flat & stable surface for welders that safely support welding pieces. Fixture tables take care of your comfort by allowing you to stand or sit while welding. They also take care of incredibly high temperatures and support high power machinery. GPPH welding tables are built with taking all the welding ergonomics into consideration. They have adjustable moving wheels for portability on the shop floor. They are electrically conductive, which allows you to connect a ground to the table instead of the metal pieces that you’re welding.

WHEN CHOOSING A WELDING TABLE, THINGS YOU SHOULD CONSIDER ARE:

1) Size of the table:

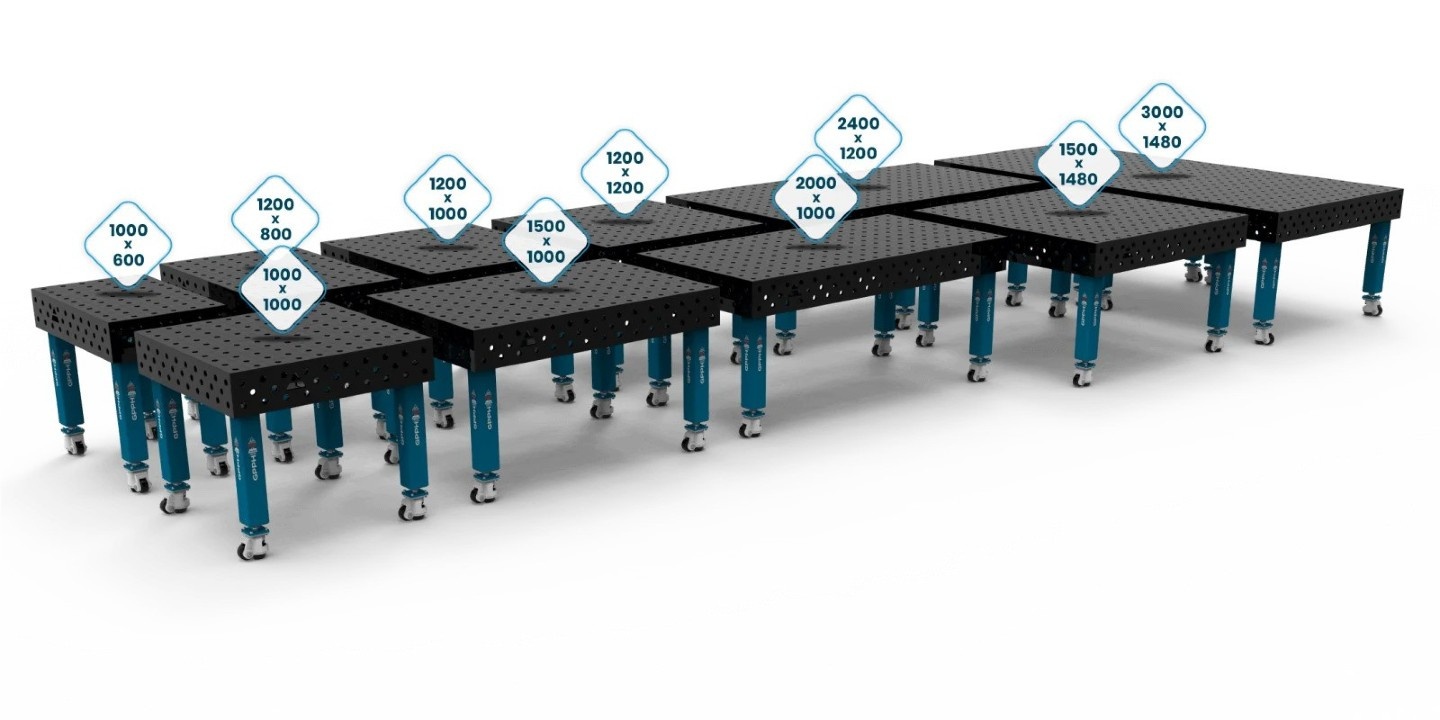

Fixture tables comes in various sizes and shapes. Starting from 1 x 1m and goes up to more than 5m in length. These table with modular sizes in order to adjust the table sizes for different work projects.

If your welding projects have big and heavy metals involved it is better to go for larger tables. If your projects are smaller in dimensions but heavier (greater than 2 tons) in weight, it is better to go with 25mm thickness tables rather than smaller 16mm thick.

2) Hole center distance:

The standard hole center distance of welding tables is 50mm. When your welding projects are larger in size it is better to go with a 100 mm distance in order to reduce the table cost.

3) Legs:

In standard configuration, legs come with two options

- With Leveling pads

- With Castor wheels

If you have a small welding shop and YOU don’t have to move the table every now & then, go with the leveling pad option. But if you have a big shop floor or heavy work pieces & need to move from one place to another, Castor wheels are the best.

5) Type of table:

Generally, the fixture table comes with 3D, 2D, and Rotary types.

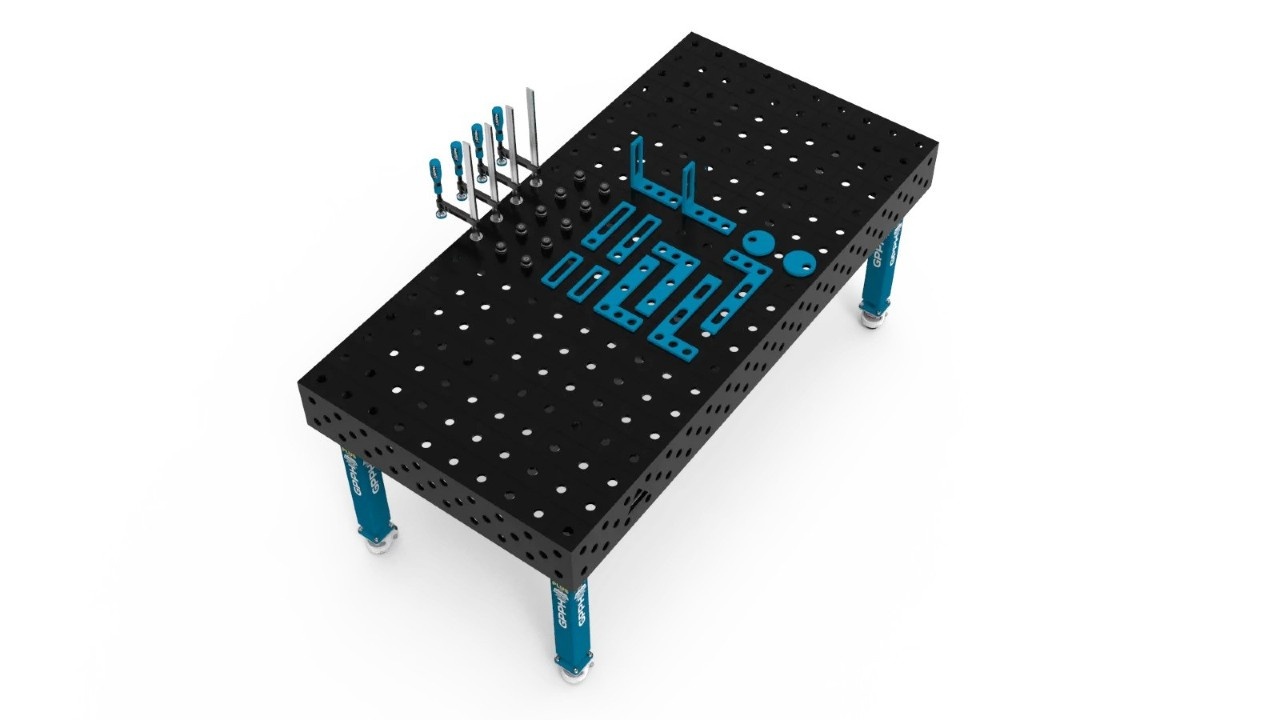

3D welding tables– Here YOU get 5 precision machined surfaces. These types of tables provide you with clamping options outside the table with help of side plates.

2D welding tables– The top surface is precision machined. Smaller workpieces can go with these types of tables.

6) Buy branded table:

Buying a branded table will always give you benefits in terms of accuracy of the table, finished materials, modularity, the welding clamps options, service they provide.

Thus, investing in a welding table would be great for your Business ROI. A welding table can increase your welding quality and provide you with a safe and stable surface. With the above information, it will be easy for YOU to pick up your best suitable welding table for your next project.

If you want to optimize your welding operations and solve issues related to inefficiency, inconsistency, and safety, a traditional welding table from GPPH Group is the answer. Explore their range to elevate your welding capabilities today.

For more information about these products, contact our sales team HERE.

Don't know which welding table to get?

Essentially, no two projects are alike. Time and budget constraints can influence the choice of welding table and equipment you decide to use. Additionally, the thickness, material, and required level of detail for your project will all impact how we achieve the final product. However, you can rest assured that the end result will be exactly what you want!

Contact the experienced Kamiteka team and tell us about your project! As a special treat, we offer a 10% discount to our welding tables - to those who mention us on their social media post. Tag us at @kamiteka_cnc and claim your 10% discount now!

(The offer is available until June 30th, 2024)

For more information about these products, contact our sales team HERE.

Welding Table Tools

|

|

|

|

Table Tools: Side Walls

What are the main advantages of the side walls in our welding tables?

First and foremost, they allow you to easily enlarge the working area with the installation of extensions or connection cubes. This makes it possible to work on larger welded parts more comfortably and efficiently. In addition, on the side walls, as well as on the table top, you can mount flat and spatial tools, which form the base for your welded constructions.

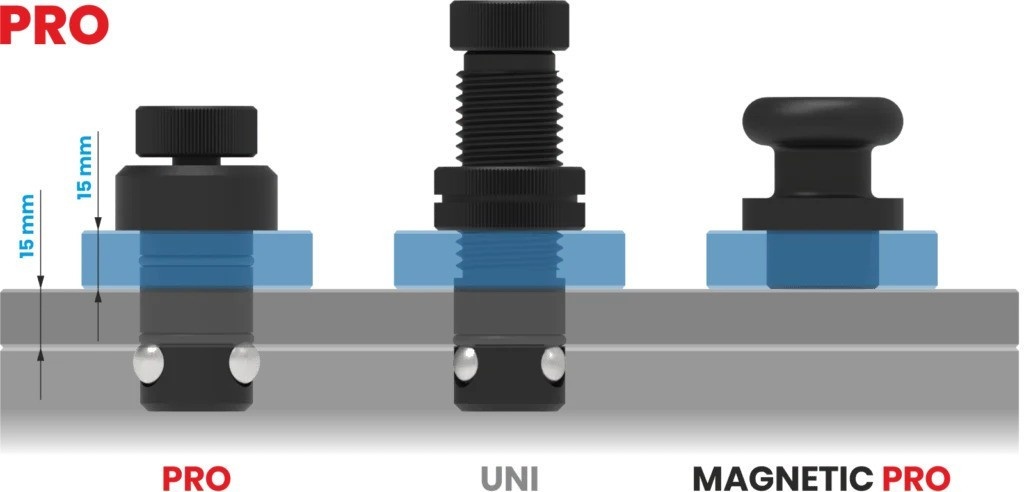

Table Tools: Assembly Bolts

The main advantage of these fast assembly bolts is the ease and speed of installation. They can be fitted easily and efficiently into the holes of the tool table, allowing the welding station to be prepared in no time. This is particularly important for frequent tool changes and quick transitions between different projects.

MB "Kamiteka" | Vilties str. 11, Vilnius | Tel: +370 600 39776 | info@kamiteka.eu