Volter Series ACP

back.png)

VOLTER ACP series CNC Routers are specially designed for processing of composite panels (ACP), HPL panels, fiber cement boards and aluminum sheets.

These machines have processing area from 3,200*1,610mm to 6,200*2,150mm. This dual spindle version allows to process materials faster, more efficiently and at reduced cost. Processed materials can be easily fixed by vacuum hold down or mechanically.

Like other VOLTER CNC Routers, the ACP series has a heavy steel frame with thermal stabilization.

| Controller | VOLTER CS |

| Max travel speed on X and Y axes, mm./sec. | 500 (30 m./min.) |

| Max travel speed on Z axis mm./sec. | 100 (6 m./min.) |

| Max thickness of material , mm. | 160 |

| Spindle power, kW | 4.5 to 6.6 |

| Spindle rotation speed, RPM | from 1 000 to 24 000 |

| Tool clamping | mechanical or pneumatic |

| Type of drives for X and Y axes | Servo, planetary gear heads, helical racks |

| Type of drive for Z axis | Servo, ball screw |

| Control panel | 15" touch monitor |

| Model | Processing area | Dimensions | Weight, kg |

|---|---|---|---|

| VOLTER ACP3016 | 3 200 * 1 610 mm | 4 300 * 2 100 * 1 600 mm | 1 500 |

| VOLTER ACP3020 | 3 200 * 2 150 mm | 4 300 * 2 600 * 1 600 mm | 1 800 |

| VOLTER ACP4016 | 4 200 * 1 610 mm | 5 300 * 2 100 * 1 600 mm | 1 600 |

| VOLTER ACP4020 | 4 200 * 2 150 mm | 5 300 * 2 600 * 1 600 mm | 2 200 |

| VOLTER ACP6016 | 6 200 * 1 610 mm | 7 300 * 2 100 * 1 600 mm | 2 600 |

| VOLTER ACP6020 | 6 200 * 2 150 mm | 7 300 * 2 600 * 1 600 mm | 3 100 |

Basic configuration:

- Vacuum table

- Tool length sensor

- Brush foot

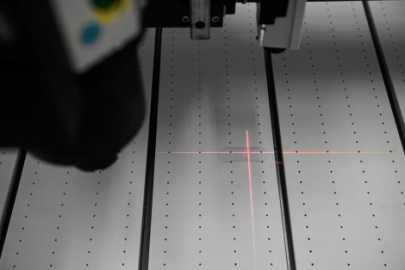

- Laser pointer

- Helical racks

Options:

- Tool lubricator

- Vacuum pump

- Dust collector 3kW with 2 bags

- Dust collector MasterVac TS220

- Vectric VCarve Pro software

.png)

.png)

.png)

.png)

.jpg)

.png)

.jpg)