LMTP6030

back.png)

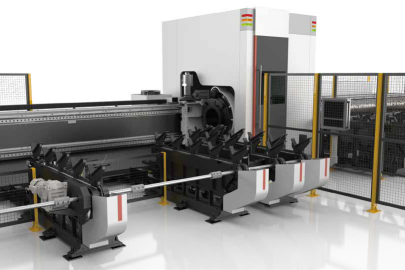

The fast-speed full automatic CNC tube laser cutting machine of LeMans can cut circle tubes, rectangular tubes and other irregular-shaped tubes. The new tube laser processing production line not only implements automatic production, but also breaks through the limitation of plane cutting. Achieved multi-dimensional cutting, it is the optimal choice for metal tube laser cutting.

CNC laser tube cutting machine able to Cut, Drill, Kerf by laser, with automatic control system, able to cut complex shape in one shot, no reprocessing require after laser cut. Solution widely used in cutting varieties of metal tube (carbon steel, stainless steel, low ally steel,...

TP Series Tube Laser Cutting Machine is specifically designed for high volume tubes or pipes cutting, providing far greater efficiency than normal laser systems when cutting pipes and tubular metals.

The TP series laser tube cutting machine can perform high-speed, high-quality laser cutting on round tubes, square tubes, rectangular tubes, and oval tubes. series laser tube cutting machine adopts gantry structure, motor gear rack drive , transmission components such as gearbox, guide rails and rack and pinion, which are all well-known foreign brands It is featured by stable structure, good rigidity, light weight, and high dynamic response It is a high-performance laser tube cutting machine. .

- Advanced chuck clamping system

- Automatic spindle support

- Expert database system

- Thermostatic control cabinet

- Panasonic/Yaskawa servo systems

- Raytools auto-focus laser cutting head

| MODEL | LMTP6030 |

| CNC System | FSCUT |

| Power | 1500W,2000W,3000W |

| Size |

11.6mx 2.5mx 2.6m |

| Material Type |

Carbon steel or stainless steel round tube, square tube, rectangular tube, elliptical tube, angle iron, channel steel, H-shaped steel, etc. |

| Material Diameter |

10mm~220mm |

| Loading Capacity |

5000mm~6300mm |

| Unloading Capacity |

0~3000mm |

|

Single Tube Max. Weight |

25kg/m (150kg) |

|

Total Power (reference) |

38kW |

|

Phase Number/Power Supply/Rating/Voltage Frequency |

3/380V/50Hz, Voltage Fluctuation<10% |

|

Working Air Source |

0.5 ~ 0.8 MPa |

|

Working Area (machine tool) |

Y 0 ~ 6000mm X 0~200mm Z 0 ~ 170mm |

|

C1/C2 Axis |

n*360° |

|

X/Y Positioning Accuracy |

±0.05mm/500mm |

| MODEL | LMTP6030 |

| CNC System | FSCUT |

| Power | 1500W,2000W,3000W |

| Size |

11.6mx 2.5mx 2.6m |

| Material Type |

Carbon steel or stainless steel round tube, square tube, rectangular tube, elliptical tube, angle iron, channel steel, H-shaped steel, etc. |

| Material Diameter |

10mm~220mm |

| Loading Capacity |

5000mm~6300mm |

| Unloading Capacity |

0~3000mm |

|

Single Tube Max. Weight |

25kg/m (150kg) |

|

Total Power (reference) |

38kW |

|

Phase Number/Power Supply/Rating/Voltage Frequency |

3/380V/50Hz, Voltage Fluctuation<10% |

|

Working Air Source |

0.5 ~ 0.8 MPa |

|

Working Area (machine tool) |

Y 0 ~ 6000mm X 0~200mm Z 0 ~ 170mm |

|

C1/C2 Axis |

n*360° |

|

X/Y Positioning Accuracy |

±0.05mm/500mm |

.png)

.png)

.png)

.png)

.JPG)

.JPG)

.JPG)

.JPG)

.jpg)

.jpg)