LMTP10032W

back.png)

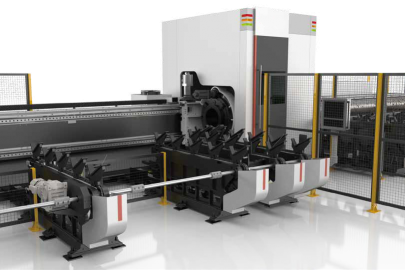

Looking to revolutionize your metal tube cutting operations? LeMans introduces the cutting-edge fast-speed full automatic CNC pipe fiber laser cutting machine, designed to elevate precision and efficiency in metalworking.

LMTP10032W 3 chucks (horizontal) laser tube cutting machine integrates CNC Technology, laser cutting, and precision machinery into one, with good adaptability. It has great advantages for medium and heavy tube processing. It is mainly used for cutting of carbon steel tube, stainless steel tube, aluminum alloy tube (square tube, round tube, OB tube, sectional materials) and other tubes. It is the first choice for the non-contact metal tube processing industry because of its professionalism, efficiency, high-cost performance.

It is widely used in petroleum tubelines, bus manufacturing, construction machinery, shelves and containers, agricultural and forestry machinery, ladder and guardrail, laser processing services and other machine manufacturing or tube processing industry.

- Large HMI interactive interface, with multiple functions such as process database, graphic display, automatic fixture control, program quick editing and modification, and etc.

- 3-chucks linkage cutting, large cutting load, high precision, can achieve zero tailling cutting.

- Equipped with a fully automatic bundling and loading system, with high automatic production efficiency.

- The machine tool is equipped with fully enclosed machine tool cover, the overall safety protection of the machine tool meets the highest international standards.

- Modular designs, can be customized according to customer requirements.

| MODEL | LMTP10032w |

| CNC System | FSCUT |

| Power |

3000W、4000W、6000W |

| Size |

17.3mx 6.5mx 2.8m |

| Material Type |

Carbon steel or stainless steel round tube, square tube, rectangular tube, elliptical tube, angle iron, channel steel, H-shaped steel, etc. |

| Material Diameter |

10mm~320mm |

| Loading Capacity |

5000mm~10000mm |

| Unloading Capacity |

0~4000mm |

|

Single Tube Max. Weight |

40kg/m (400kg) |

|

Total Power (reference) |

90kW |

|

Phase Number/Power Supply/Rating/Voltage Frequency |

3/380V/50Hz, Voltage Fluctuation<10% |

|

Working Air Source |

0.5 ~ 0.8 MPa |

|

Working Area (machine tool) |

Y 0 ~ 11000mm X 0~300mm Z 0 ~ 180mm |

|

C1/C2 Axis |

n*360° |

|

X/Y Positioning Accuracy |

±0.05mm/500mm |

| MODEL | LMTP10032w |

| CNC System | FSCUT |

| Power |

3000W、4000W、6000W |

| Size |

17.3mx 6.5mx 2.8m |

| Material Type |

Carbon steel or stainless steel round tube, square tube, rectangular tube, elliptical tube, angle iron, channel steel, H-shaped steel, etc. |

| Material Diameter |

10mm~320mm |

| Loading Capacity |

5000mm~10000mm |

| Unloading Capacity |

0~4000mm |

|

Single Tube Max. Weight |

40kg/m (400kg) |

|

Total Power (reference) |

90kW |

|

Phase Number/Power Supply/Rating/Voltage Frequency |

3/380V/50Hz, Voltage Fluctuation<10% |

|

Working Air Source |

0.5 ~ 0.8 MPa |

|

Working Area (machine tool) |

Y 0 ~ 11000mm X 0~300mm Z 0 ~ 180mm |

|

C1/C2 Axis |

n*360° |

|

X/Y Positioning Accuracy |

±0.05mm/500mm |

.jpg)

.JPG)

.jpg)

.JPG)

.JPG)