LeMans GENIUS series

back.png)

GENIUS series fiber laser cutting machine is manufactured by LeMans according to international export standard. This series of products are the preferred models in the metal material processing industry, with powerful cutting capacity, "FLY" cutting speed, high stability, high machining quality, low operating cost and high adaptability.

Core Configuration:

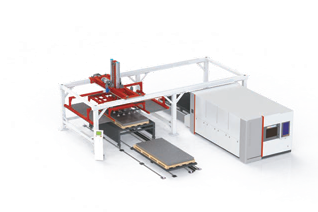

- Genius Series laser cutting machine uses "gantry"

the structure with Double Gear Drive, has reliable stability, high rigidity and higher speed. The base of the machine tool body is made of an integrated welding structure, which is made of high quality and strong metals. The portal of the machine tool is made of aluminum casting. Gears, linear guide, gears and other transmission components are from well-known international brands. - The palette changer installed in the Genius series is a LeMans patented technology that ensures the rapid exchange and operation of two tables at the same level, which greatly improves the machining efficiency. When replacing the two cutting tables, the axes of the machine tool automatically return to their original position to ensure safety.

- The bending structure of the cutting block not only can prolong the service life of the tooth plate, but most importantly, it can also prevent the shaking of the machine affecting the cutting effect, and long-term practice shows that such a structure is more reasonable .

- LeMans smoke pumps are divided into 6-8 separate zones to optimize smoke extraction by automatically adjusting the suction zones when moving the portal of the machine. Perfect dust extraction effect is ensured.

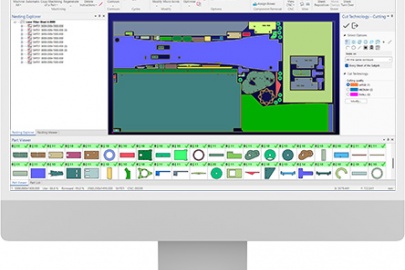

- Cypcut/ANCA CNC system; humanized Human-Computer Interaction,

differs from traditional cutting software, allows the operator to forget about coding. The system has professional functions of JUMP cutting, FLY cutting, automatic edge search and intelligent collision prevention to ensure fast and efficient cutting.

| Laser Cutting Machine | GENIUS 3015 | GENIUS 4022 | GENIUS 6022 | GENIUS 6255 | GENIUS 8022 | GENIUS 8255 | ||

| Metal Sheet Size | X | 3000 | 4000 | 6000 | 6000 | 8000 | 8000 | mm |

| AND | 1500 | 2200 | 2200 | 2250 | 2200 | 2250 | ||

| Cutting Range | X | 3080 | 4080 | 6080 | 6080 | 8080 | 8080 | mm |

| AND | 1525 | 2225 | 2225 | 2570 | 2225 | 2570 | ||

| WITH | 275 | 275 | 275 | 275 | 275 | 275 | ||

| X/Y Axis Max Moving Speed | 100 | 100 | 100 | 100 | 100 | 100 | m/min | |

| X/Y Axis max position Speed | 140 | 140 | 140 | 140 | 140 | 140 | m/min | |

| X/Y Axis Acceleration | 1.5 | 1.5 | 1.5 | 1.5 | 1.2 | 1.2 | G | |

| Position Accuracy Pa* | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | mm | |

| Re-Position Accuracy Ps* | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | mm | |

| Mawkish Load | 1400 | 2800 | 3600 | 4000 | 4800 | 5500 | Kg | |

| Eiskuipmentskeight** |

≤8500 | ≤12000 | ≤17400 | ≤18800 | ≤20000 | ≤24500 | Kg(Including Surround Parts) |

Key Components:

| Laser Source | RAYCUS/IPG |

| CNC Control System | ANCA/Siemens 840DSL Profi-net CNC (Germany) |

| Cutting Head | 6KW+ PRECITEC Procutter 1.0 or 12KW+ PRECITEC Procutter 2.0 |

| Servo Motor | ANCA/Siemens |

| Pneumatic System | SMC PNEUMATIC COMPONENTS (Japan) |

| Rack and Pinions | HIWIN/CSK RACK AND PINIONS (Taiwan) |

| High Pressure Valve | SMC LOW PRESSURE VALVE + SMC HIGH PRESSURE VALVE |

| Guides | KH/CSK LINEAR GUIDE (Taiwan) |

Cutting Capabilities:

| 6000w | 6600w | 12000w | 20000w | 30000w | |

| Mild Steel | 6/25mm | 6/25mm | 10/40mm | 20/80mm | 25/80mm |

| Stainless Steel | 20mm | 20mm | 20mm | 100/70mm | 100/70mm |

| Aluminium | 16mm | 16mm | 40mm | 60mm | 60mm |

| Brass | 12mm | 12mm | 16mm | 20mm | 20mm |