LeMans GF series

back.png)

— Reduced procurement costs and reduced maintenance costs

— Economical fifiber laser cutting machine, cost-effective choice.

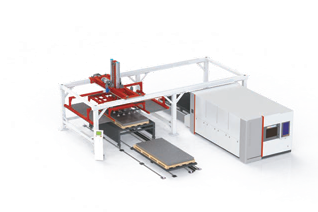

GF Series Fiber Laser Cutting Machine adopts gantry-motion structure, linear guide, screw drive, AC servo motor and drives, and vacuum system (both sides), etc. Not only that the equipment's design is advanced and reliable, but also that all key components are from international well-known brands. This special laser CNC system has advantages of high integration, better control precision and more stable operation, therefore, in addition to meeting the requirement of cutting carbon steel plate, it can also meet the requirement of cutting SS plate, aluminum alloy, copper alloy and other materials.

- The traveling gantry laser cutting machine generally includes the machine tool bed, beam and other basic components for the installation of laser cutting head, mechanical automatic processing is achieved through control system. Therefore, the drive design and manufacturing of beam device play an important role in quality processing. Especially during the cutting process, when the beam is moving, only its excellent stability and flexibility can ensure a faster processing speed and processing quality.

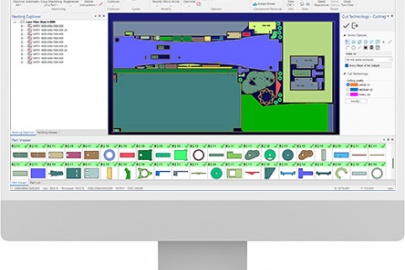

- GF3015 is equipped with international standard FSCUT Cypcut CNC control system that guarantees its high stability and reliability.

- Professional laser cutting functions: Fast-response height following, Laser Pointer:Assistance in optical path adjustment, Micro-joints Cutting, Edge-shared Cutting, Cutting-retraction, Adjustable power of corner cutting

- No lens inside laser generator, no need for maintenance.

- The laser resonator, laser cutting head and other key components all get sufficient cooling to ensure the machine's smooth and safety running

Cutting Capabilities:

|

3000w |

4000w |

6000W | 6600W | 12000W | 20000W | 30000W | |

|

Mild Steel |

2/22mm |

3/25mm |

6/25mm |

6/25mm |

10/40mm |

20/80mm |

25/80mm |

|

Stainless Steel |

10mm |

12mm |

20mm |

20mm |

40/30mm |

100/70mm |

100/70mm |

|

Aluminium |

8mm |

10mm |

16mm |

16mm |

40mm |

60mm | 60mm |

| Brass | 6mm |

8mm |

12mm | 12mm | 16mm | 20mm | 20mm |

TECHNICAL PARAMETERS

|

Model |

L.M. 3015 GF |

L.M. 4022 GF |

L.M. 6025 GF |

L.M. 8025 GF |

L.M. 10025 GF |

L.M. 12025 GF |

|

Processing area X (mm) |

1530 |

2230 |

2530 |

2530 |

2530 |

2530 |

|

AND |

3050 |

4050 |

6050 |

8050 |

10050 |

12050 |

|

WITH |

250 |

250 |

250 |

250 |

250 |

250 |

|

Max. positioning linkage speed(m/min) |

140 |

140 |

140 |

140 |

140 |

140 |

|

Acceleration |

1.2G |

1.2G |

1.2G |

1.2G |

1.2G |

1.2G |

|

Positioning accuracy Pa*(mm) |

0.05 |

0.05 |

0.05 |

0.05 |

0.05 |

0.05 |

|

Repeated positioning accuracy Ps*(mm) |

0.03 |

0.03 |

0.03 |

0.03 |

0.03 |

0.03 |

|

Laser power |

3000-12000W |

|||||

Standard Parameters (3015 Model)

|

Machine model |

3015 |

|

Machine type |

Closed-type |

|

Type of laser source |

Fiber |

|

Rated power, W |

3000W |

|

Manufacturer of laser source |

Raycus/IPG |

|

Automatic focus laser cutting head, mm |

Precitec Lightcutter 2.0 Autofocus / Raytools Autofocus |

|

Z-axis travel, mm |

~0-250 |

|

Number of tables |

2 pcs |

|

Maximum movement speed for X, Y axes, m/min |

140m/min |

|

Laser positioning marking |

Yes |

|

Internal video camera for remote monitoring |

2 pcs |

|

Acceleration, G |

1.5G |

|

Positioning accuracy, mm |

+/- 0.05 |

|

Repeatability, mm |

+/- 0.03 |

|

Managing Monitor |

LCD 17” |

|

Software |

Cypcut/Hypcut FSCUT |

|

Monitoring monitor |

LCD 24” |

|

Materials to be cut |

Steel, Stainless steel, Aluminium, Galvanized steel |

|

Smoke filtration system |

Option |

|

Automatic lubrication system |

Yes |

|

Voltage stabilizer |

Yes |

|

CE certificate |

Yes |

|

Chiller |

Yes |

|

Main frequency |

50 Hz |

|

Power supply, V/Hz |

380/50 ± 5% |

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.JPG)

.jpg)

.JPG)